In any environment where uptime and performance are paramount, preventive maintenance plays a vital role. This proactive approach involves regularly inspecting, servicing, and maintaining equipment before failures occur. It’s like taking your car for regular oil changes and tune-ups but for the critical infrastructure keeping your operations running smoothly.

Introduction to Preventive Maintenance

Preventive maintenance stands as a pivotal strategy within various industries, aimed at identifying and rectifying potential issues before they escalate into significant problems. This proactive approach ensures the longevity and reliability of essential machinery and systems, safeguarding against unexpected downtimes and costly repairs.

The Importance of Preventive Maintenance

In critical environments where every second counts, the role of preventive maintenance must be balanced. It encompasses a range of practices, from routine inspections to scheduled servicing, all designed to maintain equipment in peak condition and prevent failures that could disrupt operations.

Preventive maintenance offers numerous benefits:

- Reduced downtime: By identifying and addressing potential issues early, you can prevent them from escalating into costly, disruptive breakdowns.

- Extended equipment lifespan: Regular maintenance helps your equipment last longer, saving you money on replacements.

- Improved efficiency: Well-maintained equipment operates at peak performance, reducing energy consumption and optimizing your operations.

- Enhanced safety: By proactively identifying and addressing hazards, you can create a safer environment for everyone.

Types of Preventive Maintenance

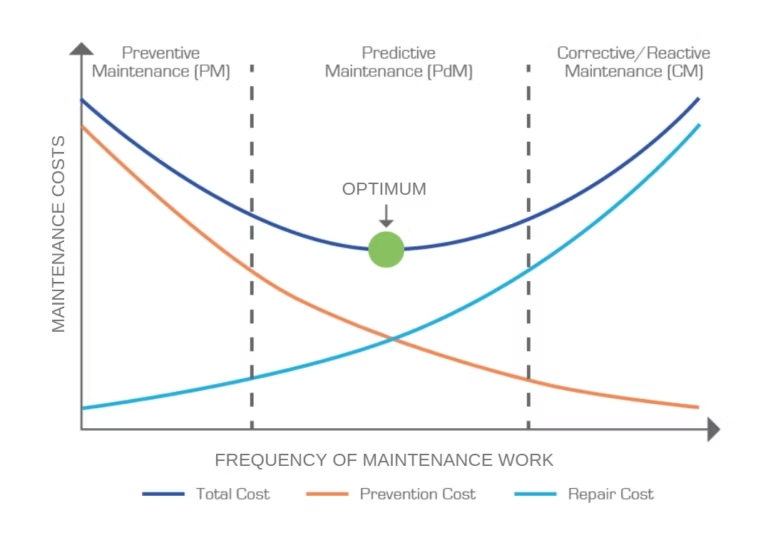

Preventive maintenance is categorized into various types, each tailored to specific operational needs:

- Usage-Based Maintenance: Triggered by the operational hours or cycles of equipment, ensuring maintenance aligns with actual usage patterns.

- Calendar/Time-Based Maintenance: Scheduled at regular intervals, regardless of equipment usage, to maintain consistent performance.

- Predictive Maintenance: Utilizes real-time data and analytics to predict when maintenance should be performed, optimizing the maintenance schedule.

- Prescriptive Maintenance: Goes a step further by not only predicting when maintenance is needed but also prescribing the best course of action.

Implementing Preventive Maintenance

The success of a preventive maintenance program lies in its meticulous implementation:

- Asset Inventory: A thorough listing and assessment of all equipment and assets subject to maintenance.

- Maintenance Scheduling: Development of a detailed maintenance calendar based on the type and usage of each asset.

- Condition Monitoring: Continuous monitoring of equipment conditions to identify early signs of wear or failure.

- Data Analysis: Leveraging data collected from monitoring and inspections to make informed maintenance decisions.

Why Preventive Maintenance is Crucial for Data Centers

Data centers house the sensitive IT infrastructure that powers our modern world. Downtime in a data center can have catastrophic consequences, leading to lost revenue, data breaches, and reputational damage. This makes preventive maintenance absolutely essential for data center operations.

- High complexity: Data centers contain complex equipment with numerous interconnected components. Regular maintenance ensures each component functions optimally and prevents cascading failures.

- Costly downtime: A brief outage in a data center can cost millions of dollars. Preventive maintenance minimizes downtime risk and protects your bottom line.

- Data security: Data breaches often originate from vulnerabilities in IT infrastructure. Regular maintenance helps secure your data by identifying and addressing potential security risks.

Data centers operate in a demanding environment with sensitive equipment exposed to various stresses, including:

- High temperatures: Data center equipment generates significant heat, which can damage components if not properly managed.

- Dust and debris: Dust and debris buildup can clog filters and interfere with airflow, leading to overheating and equipment failure.

- Power fluctuations: Power surges and outages can damage sensitive equipment and disrupt operations.

- Vibrations: Vibrations from nearby equipment can damage sensitive components.

Challenges and Solutions in Preventive Maintenance

Despite its benefits, preventive maintenance presents challenges such as accessibility issues, high costs, and time constraints. Solutions include the adoption of advanced technologies like drones for inaccessible areas, risk-based prioritization to manage costs, and the integration of maintenance software for efficient scheduling.

Tips for Data Center Maintenance

Implementing a successful preventive maintenance program in your data center requires careful planning and execution. Here are some key tips:

- Develop a comprehensive maintenance plan: Identify all equipment in your data center and create a schedule for inspections, cleaning, and other maintenance tasks based on manufacturer recommendations and usage patterns.

- Invest in the right tools and resources: Utilize specialized tools and software for monitoring equipment health, identifying potential issues, and streamlining maintenance activities.

- Track and analyze data: Monitor the effectiveness of your maintenance program and make data-driven decisions to improve its efficiency and effectiveness.

- Consider predictive maintenance: As technology evolves, consider incorporating predictive maintenance techniques that leverage sensors and data analytics to predict equipment failures before they occur.

As we look to the future, the role of preventive maintenance in ensuring the reliability and efficiency of critical environments is undeniable. Preventive maintenance is not just an option for data centers; it’s a necessity. By proactively maintaining your critical infrastructure, you can ensure reliability, optimize performance, and protect your business from costly disruptions.